Privacy, Trust, and Reliability with Real-Time Command and Control of Industrial Assets

Self-Diagnosing, Self-Healing Digital Twin Environments.

To Contact Us:

95 Dublin Drive

Phone: 925.788.6076

Email:

info@freddy.io

Pleasant Hill, CA 94523

USA

Twitter:

EVOLVED SUPPLY CHAIN

Facebook:

EVOLVED SUPPLY CHAIN

What is the Evolved Supply Chain™? |

These tools help manage the Acquisition, Deployment, Operation, Maintenance, and Disposal of Industrial and Other Assets.

Twenty-first Century Sustainability is based on adaptability and flexibility rather than number, size or strength.

Constant scaling is required--up, out or down with equal ease, and all is market driven.

Fifty-two Percent of Fortune 500 Companies from the Year 2000 Are Extinct

Frequent radical transformations may be required as Supply Chains grow efficient at an ever increasing rate.

Integrate your Ecosystem!

Survival comes down to

"Integrate or Be Integrated."

(pics from aspire blog)

Self-Diagnosing, Self-Healing Digital Twin Environments.

In The News

|

Our founder has written a

book

with two colleagues on decision making for our core actitivity in the Industrial 4.0 Internet of Things (IIoT) Infrastructure Development and Management.

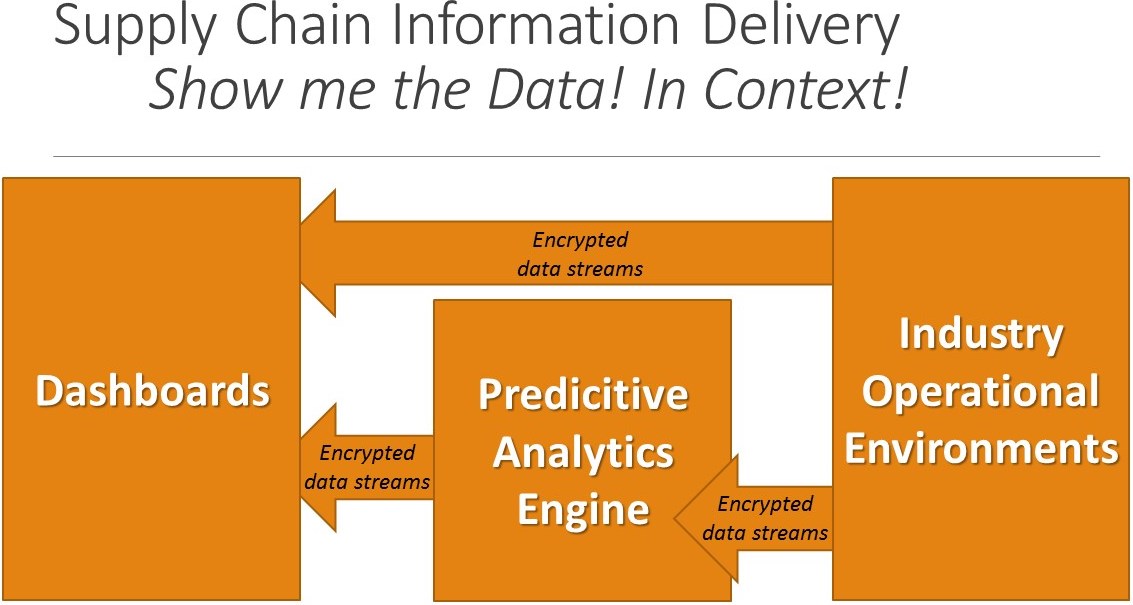

This core activity is based on analytics derived from Maintenance Repair Operations Data from deployed assets in the Internet of Things space.

|

Current Things of Interest

2023Q1

ESC™ OutlookWe began with Forklifts in Warehouses, Transloading Facilities, and, generally, Conveyance Vehicles.

|

|

|

"Save money and time!!"

FREDdySays® |

|

Our current investment in products for value extraction:

Evolved Supply Chain™

In our initial forklift use case, workloads and equipment in the Global Supply Chain are being instrumented to improve safety, performance,

and productivity through monitoring and control with predictive analytics.

Current industry belief is that in the US, Industrial Safety can be reduced over 40%. Farming, construction, and supply chain lead the list.

This can potentially yield $4.75B annually in direct repair cost savings, as well, for the global lift assets of $525B.

Industrial Digital Infrastructure (aka #Industry4dot0, #I40).

Given our ready-to-buy product marketing focus, with participation in this Core Repair Capability,

this promises early recurring revenue flows that grow from persistent return on fleet Industrial Assets.

The ESC™ Business Environment as a Service (BEaaS) is a strategic platform for long term value participation in capital formation in emerging industrial infrastructure asset management.

"#IIoT #MRO #PredictiveAnalytics #Forklifts"

Catch phrase:

|

2023 Activites

Multi-Cloud Deployment of our Application Platform for Asset Maintenance Repair Operations (MRO SaaS)

in our cloud Business Environment as a Service (BEaaS)

in our cloud Business Environment as a Service (BEaaS)

Presenting ESC™ Shop in a Box™

Blue Star Repair Service® Work Order Business Process

Demo of Evolved Asset Maintenece Repair Operations (MRO) Work Order (MROWO®) Service

|

|

|

ESC Digital Twin processing in the Industrial Asset IoT space.

Shop in a Box: managing repair shops and their associated services.

|

Coming soon: the Tutorial Guide to the next decade for Digital Twin Architecture and Intelligent Agent Methods

| ||

Available since 2017

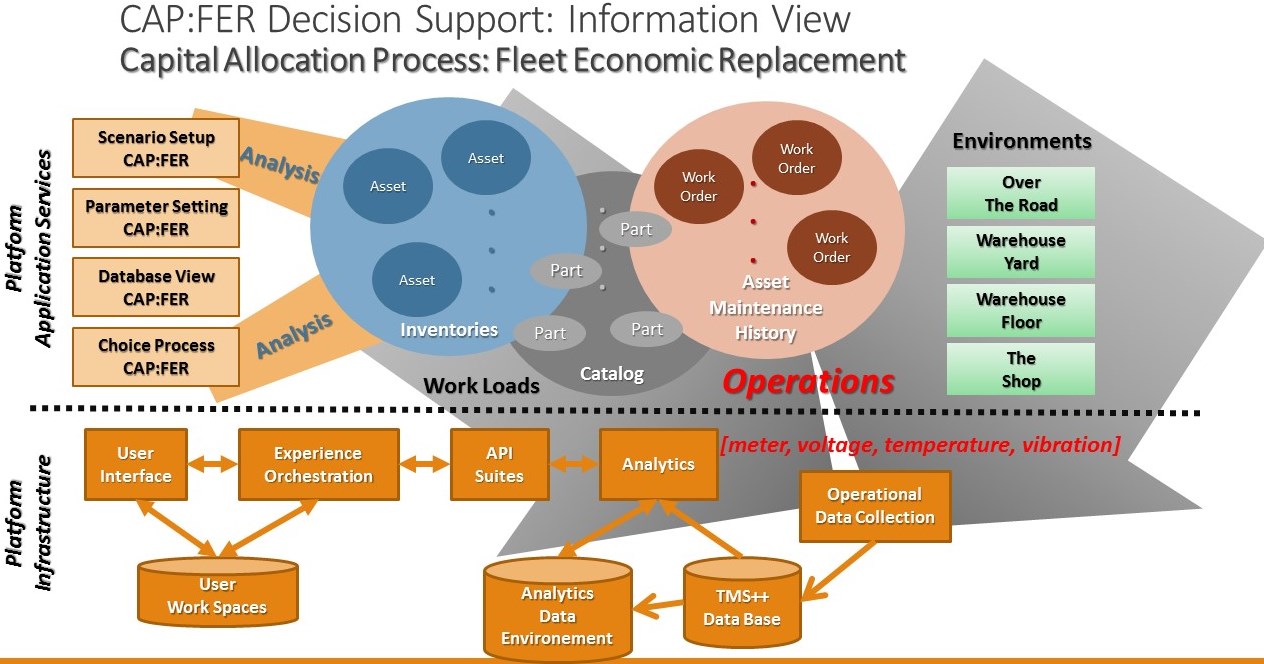

Initial Offering--CAPFER®, Fleet Economic Replacement Decision Support

Applying the ESC™ Fleet Economic Replacement Analytics

CAPFER® Application Business Process

Demo of CAPFER® Analytics< To run a demo, fill in the input information below andclick on "Calculate" button:

When Step (4) is finished executing, |

Click

CAPFER® for a description of the diagram below.

|

Industrial Asset IoT:Forklift Scenario |

|

|

For a business case description of the culmination of the last 4 years:

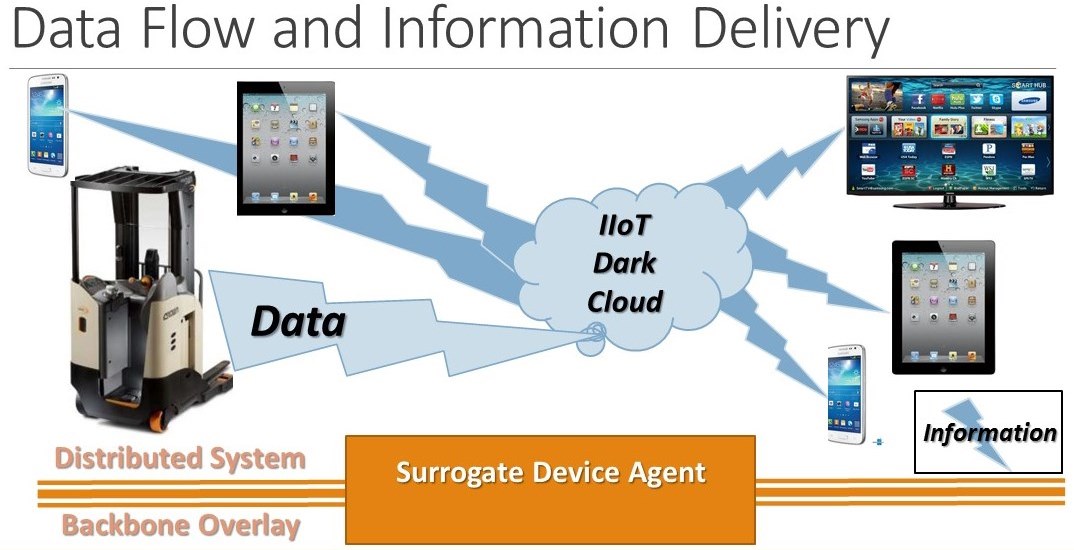

NGE activities in the Industrial IoT space. Information Delivery actuates Knowledge of Decision Makers.

These Decision Makers use their Wisdom to choose the best options for Actions.

|

Industrial Asset Management

|

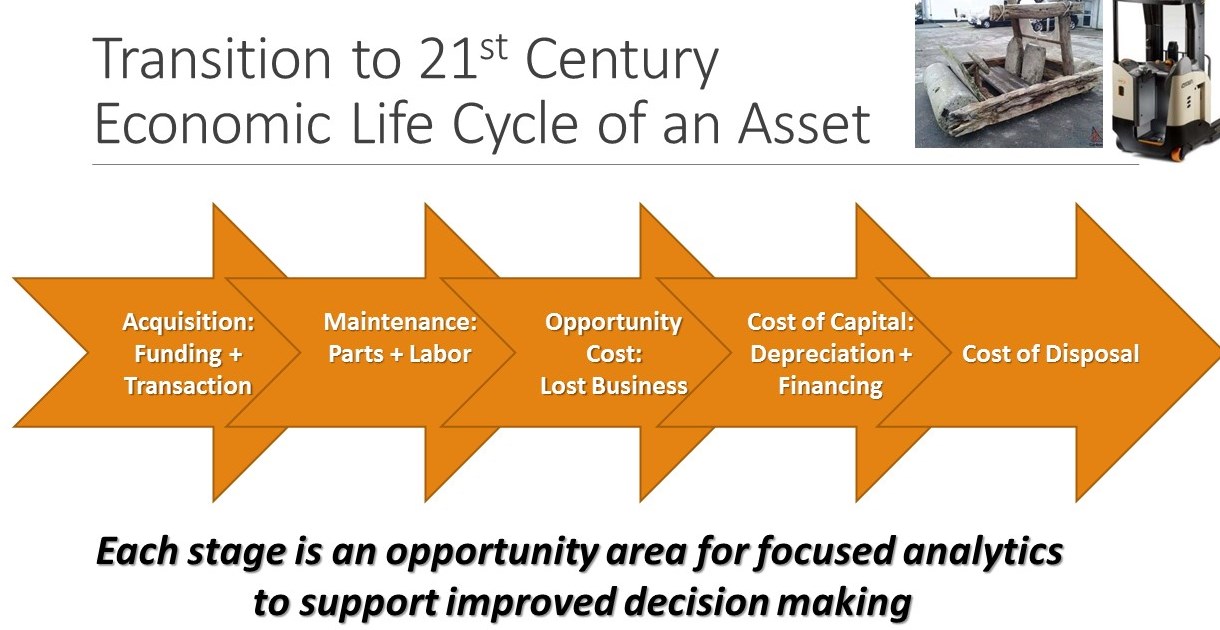

Each stage in the figure to the right is an opportunity area for focused analytics to support improved decision making on Redeploy, Repair or Replace.

21st Century Pattern: Economic Stages in the Life of an Asset

This is the largest Capital Allocation decision, generally needed to be known 18-24 months in advance.

This is the ongoing operational requirements, budgeted at least quarterly. All-in costs need to be considered: Wages + Benefits and Cost of Carry for Parts Inventory.

This involves lost or delayed work due to failures of Assets. A forklift failure on the warehouse floor not only slows the completion of its workload, but frequently interrupts other forklift movements down the blocked aisle.

This represents the steady loss of Asset value due to age plus the requirement to finance the Capital allocated to funding the Assets.

This refers to the removal of Assets from production and what is involved in selling or scrapping the Assets. It could be as little as allocated rent for a salvage yard where assets may be kept. |

|

CAPFER® Application Overview

|

|

in a Time of Fleet Management and Conveyance.

"Some Questions??" asked Holmes, rhetorically.

"Logistics, my dear Watson!", he then answered. without waiting.

How Old is the Fleet?

How Operationally Efficient is the Fleet?

How Economically Efficient is the Fleet?

The diagram at the left is the Master Business Architecture. |

ESC™ Associate/Partner Expertise and Experience

Deep business expertise with over 200 years of experience that centers on all aspects and sectors of Financial Services, Capital Markets and Investment Banking. We have significant experience in Health Care Information Systems and large-scale Printing Systems. Technology experience is broad and deep covering strategy, application development, infrastructure development, and last, but not least, training.

|

What is our competitive advantage?Assisting individuals and firms to profit in the change and complexities of modern markets and technologies.Success of IT actions should be a matter of maintaining up-to-date knowledge and managing options with positive expectancy--do things that have positive expected outcomes based on best information These outcomes may not always be realized, but if they are, they contribute to value building. Positive expectancy is a lot like Warren Buffett's Rule #1: Never lose money. |

|

How do we help build value?

|